Overview

This article demonstrates how to create a meter based nested preventive maintenance. Nested preventive maintenances, or nested PM's, permit structured scheduling of maintenance events that are dependent on other events. To set up maintenance tasks that are periodic, and tied to another event, a user is able to specify the parent event, and the occurrence of the other child events. The events occur at specific intervals.

Note:- This feature is not compatible with multi-asset scheduled maintenances

Meter reading based nested PM

Example: Let's say we have a machine that gets serviced every X hours. The complexity of the task increases with the size of the interval between servicing. The manufacturer recommends the following:

- Grease & Oil change every 500 hrs

- Oil filter & air filter change every 1000 hrs

- Realign the motor shaft every 3,000 hrs

- Replace the bushings every 10,000 hrs

- Replace the bearings every 25,000 hrs

When the technician is replacing the bearings at 25,000 hours, it makes sense to grease & oil change and then filter changes too.

Setting up a time based nested PM:

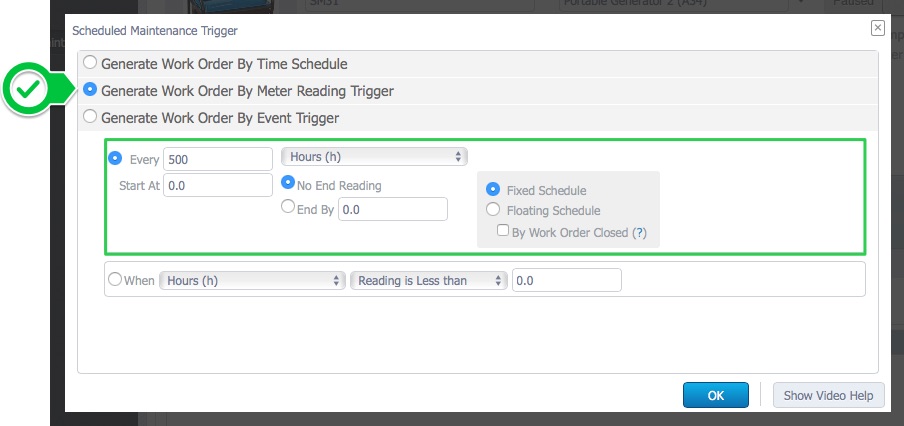

1. Follow the procedure to set up a regular scheduled maintenance. Configure your trigger to be the lowest interval in your nested PM like this:

2. Next, click Nested PMs, and New

3. This is where you set up the Nested Events. Nested PM functionality assumes that the organization combines all tasks from the more frequent cycles, into less frequent cycles. For example, 500hr, 1000hr, 3000hr, 10000hr PM tasks are included in the final 25000hr PM task list. In this case, every cycle is a multiplier of the base 500hr PM cycle:

PM Cycle |

Multiplier |

Root Code |

500hr PM |

1 |

N1 |

1,000hr PM |

2 |

N2 |

3,000hr PM |

6 |

N3 |

10,000hr PM |

20 |

N4 |

25,000hr PM |

50 (25 x 5) |

N5 |

4. By clicking New, you will be presented with a window for configuring the Nested PM. Add the next nesting cycle.

- Summary of PM - Name the PM. In this case, the we'll call it 1000hr PM

- Parent - The N1 code is always your root cycle. Everything else is a multiplier of that. In this case, the root is the 500hr PM.

- Multiplier - As the 1000hr cycle happens every second 500hr cycle, the multiplier is 2.

5. Repeat the process for other cycles:

6. Click Labor Tasks, add the tasks or task groups, and assign them to their corresponding cycle (N1, N2, N3, N4 etc.)

7. Next, the Nested PM start point needs to be configured. If the scheduled maintenance is triggered now, the next iteration cycle is N1 so it will trigger a 500hr PM.

To change the starting point, click Nested PMs and Change.

8. Let's say the next PM is the 10,000hr PM (20th iteration). Then the starting iteration needs to be adjusted to the 19th iteration. Click on the iteration.

This means the current cycle is N1 and the next will be the N1, N4 and N2. This is the 500hr, 1000hr and 10,000hr PM combined.

9. Click save. Click Paused to activate the PM.